LIGHT AND ENERGY

CONTROL FOR YOUR

COMFORT

Incorporated in 1983, Vitrum & Glass benefits from its long experience in the production of high quality insulated glazing units.

Vitrum & Glass

The company has gained a reputation for constant updating of its quality standards and the level of services offered.

The first manufacturer in Italy to install a production line for TPS® insulated glazing units, Vitrum & Glass invests in R&D to experiment with new technological solutions to offer products and services of the highest standards.

INSULATED GLAZING ASSEMBLY LINE WITH TPS® APPLICATOR

Vitrum & Glass boasts an IGU production line that incorporates the latest technological advances for the production of large-size, structural, stepped and safety glazing units. The plant is also equipped with a TPS® applicator.

TPS is today's most advanced solution for the latest generation of insulated glazing units.

THERMO PLASTIC SPACER

The TPS® or “thermal plastic spacer” is composed of a single polyisobutylene-based component with integrated desiccant.

The TPS® thus replaces conventional metal profiles, offering a significant increase in insulating performance.

All the main certification institutes, including Ift Rosenheim and TÜV Rheinland, confirm the following characteristics:

• improved linear thermal transmittance (Psi value) by up to 57%

• improved temperature distribution on glass

• reduction of edge condensation effect

• marked reduction of structural tensions acting on the glass

• efficient sealing that guarantees humidity protection and perfect gas tightness

Maggiori informazioni

THERMO PLASTIC SPACER - Advanced insulated glazing unit

Download PDF Eng

TPS® is currently used in millions of glazing units installed in the most technologically sensitive European countries, including Germany, Austria, and Switzerland, and is suitable for residential and commercial applications.

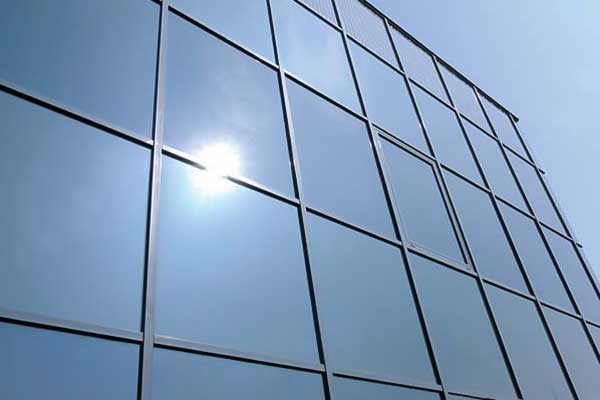

Structural insulated glazing

Some applications require insulated glazing units assembled with special structural UV resistant silicone sealants.

These silicone adhesives are specifically formulated for applications requiring high strength, in which the use of normal polysulphide sealants would result in an unacceptable increase in joint dimensions.

For the construction of curtain walls, structural glazing units can be made with the stepped assembly system.

For aesthetic reasons, glazing with printed borders that mask the facade frame is becoming increasingly popular thanks to the associated appearance of visual continuity.

Holes can be drilled into the stepped edge of the units to install handles or accessories.

Each stage of the production process is performed internally, with exceptional technical mastery and flexibility.

SOME Stepped structural

Stepped structural unit

Stepped structural unitwith ground mitre edge

Stepped structuralunit with hole for handle

GLAZING Units with integral blinds

Vitrum & Glass specialises in the manufacture of insulated glazing units with the ScreenLine® system, in which the blind is assembled inside the cavity between the two panes.

Operation of the blind, whether manual or electrical, has no effect on the insulating properties of the unit and takes place in a completely sealed space.

Architects can select the most suitable glazing composition and ScreenLine® system for each project, whether residential or commercial.

ScreenLine® blinds are available in three versions:

Venetian

roller

pleated

Main strengths of the ScreenLine® system:

since it is housed in the glazing unit cavity, the blind never needs cleaning, never gets damaged, and never requires maintenance

protects from light and heat, offering privacy with a minimalist style that respects and enhances a wide range of architectural settings

More info

SCREEN GLASS - Il vetro che non c’era

Download PDF Ita-Fr

hand-made insulated units with sash-style window profiles

Vitrum & glass combines its technological expertise with the artisanal skills of former times to create profiles for the production of classic style insulated glazing.

automated glassstorage system

Our automated warehouse allows the storage and handling of more than 150 types of monolithic and laminated glass.

Cutting lines

The cutting lines connected to the automated warehouse allow us to process monolithic and laminated sheets including very large sizes.

LOGISTICS

High production volumes call for a flexible and rapid logistics system that guarantees total customer satisfaction.

Collaboration with specialised haulage companies is the gateway to building a logistics structure of modern conception.

The service is characterised by:

care devoted to packing and transport

ample protected storage facilities

logistical efficiency

Creating a synergic network with partners and suppliers and joining forces with GLASS group have allowed us to develop and expand our know-how, enabling us to keep improving the services offered to customers.

Strategia di Specializzazione Intelligente

Il progetto di innovazione di Vitrum & Glass rientra nella Strategia di Specializzazione Intelligente regionale che si propone di sostenere gli investimenti produttivi connessi ai percorsi di

consolidamento e diversificazione, al fine di conseguire un potenziamento della base produttiva regionale, il suo sviluppo tecnologico e la sua competività.

Azione 3.1.1 del POR FESR Liguria 2014-2020

Azione 3.1.1 e 3.2.1 del POR FESR Liguria 2014-2020

Azione 2.1.2. del PR FESR 2021-2027